Ensuring Optimal Performance of Your Pneumatic Tube System: Why Carrier Maintenance Matters

The pneumatic tube system (PTS) is a vital piece of infrastructure in hospitals, acting as the logistical backbone for the fast and efficient transport of critical items like blood samples, medications, and other medical goods. In the past, clinical staff were responsible for physically transporting these items between departments. Today, thanks to PTS, those items reach their destinations faster, reducing wait times and improving hospital workflows. However, while digital communications have revolutionized document management, medical goods still rely on the old but reliable pneumatic tube system. The question is: are your pneumatic tube carriers in the best condition to keep this system running smoothly?

The Importance of Pneumatic Tube Systems in Hospitals

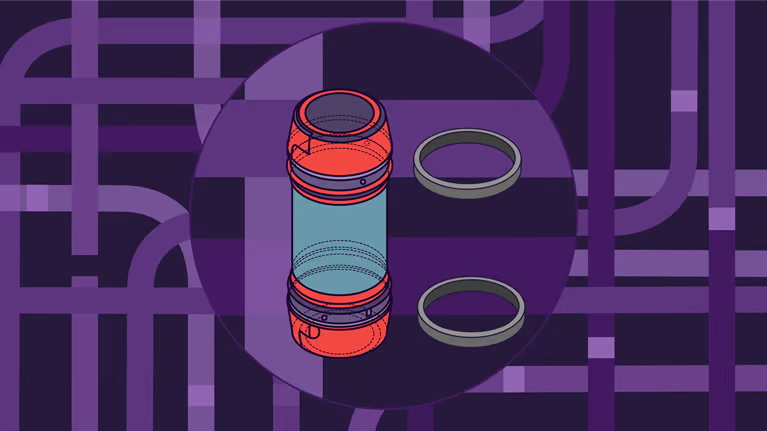

A pneumatic tube system is indispensable to modern hospital operations. It ensures the rapid delivery of medical goods between wards, laboratories, pharmacies, and other departments without requiring manual transport by staff. These carriers, which measure 33 cm in length and up to 16 cm in diameter, can travel at speeds of up to 6 meters per second, carrying loads of nearly 2 kilograms. Made from durable, transparent plastic, these carriers are designed for easy inspection. Their colored caps allow for simple categorization by contents, urgency, or department, adding an extra layer of efficiency.

Thanks to built-in RFID transponders, carriers can be easily returned to their designated stations after use. Alternatively, the system itself can manage the distribution of empty carriers based on the current demand, ensuring that every station remains stocked and ready for use.

Why Carrier Maintenance is Critical

Although pneumatic tube systems differ from hospital to hospital, one thing is constant: high standards of quality and maintenance are essential to ensure the safe and efficient transport of medical goods. Without regular checks and maintenance, your carriers could fail to perform as needed, risking the safety of valuable medical items.

Here are the key components you should inspect regularly:

Velcro Rings: Ensure both Velcro rings are in good condition. If they wear down over time, they may cause friction inside the tubes, potentially slowing down transport or even causing the carrier to get stuck.

Opening Mechanisms: Check the closure mechanisms on the containers to ensure they are properly aligned. Any issues with the hinges or seals could result in accidental spills or, in the worst case, the container opening mid-transit.

Protective Materials: Ensure that protective items like foil pockets are intact and available. They help safeguard fragile or sensitive goods from potential damage.

When any of these components are compromised, the quality of the transport process is jeopardized. Worn Velcro rings, for example, can cause friction and slow down the carrier’s travel. Worse yet, the carrier might arrive too quickly at its destination, leading to damage or spillage. Regularly inspecting these parts ensures that your system continues to operate smoothly and safely.

When Should You Replace Parts?

Velcro Rings: Velcro rings should be replaced after approximately 1,000 runs, although this number may vary based on tube material and carrier usage. Regularly inspect the seams on the Velcro rings to ensure they are not prone to detaching, as this could lead to carriers becoming stuck or malfunctioning in the system.

Opening and Closing Mechanisms: Regularly inspect the opening and closing mechanisms to ensure that they function properly and do not open unintentionally during transit.

Cleaning: Regular cleaning is essential not only to maintain hygiene but also to extend the lifespan of your carriers. Specialized cleaning machines can help with this, preventing contamination that could affect the quality of the goods being transported.

Cleaning and Maintenance: Keeping the System Running Smoothly

The intensive daily use of pneumatic tube systems in hospitals can cause dirt and contaminants to build up inside the tubes. Whether due to wear and tear or friction, dust and liquids may accumulate over time, posing a risk to the efficiency and hygiene of the system. To combat this, hospitals use cleaning carriers, which can clear dirt and debris from the interior of the tubes. These cleaning carriers come equipped with replaceable sponges that can be easily swapped out after each use. By using the right cleaning products, you can avoid damaging the tube components while ensuring that the system remains fully functional.

Managing Your Carriers with Technology

Hospitals that rely on TranspoNet pneumatic tube systems can move up to 350 carriers during peak hours. To keep track of carrier conditions and ensure that every item is delivered safely, a software-based carrier management system is essential.

TranspoNet’s control software allows for real-time management of carrier stocks. It records which home station each carrier belongs to, the total number of carriers at a station, and how many transports each carrier has completed. This information is invaluable for assessing the condition of individual carriers and scheduling maintenance as needed. After maintenance, the software can reset the transport counter to keep everything organized.

In general, pneumatic tube carriers should be replaced after about five years of use, depending on how often they are used. The system’s software makes it easy to track each carrier’s usage, ensuring timely replacement before the carriers begin to deteriorate.

Conclusion: Keep Your Pneumatic Tube System in Top Shape

The efficiency of your hospital’s pneumatic tube system depends heavily on the condition of the carriers. Regular checks and maintenance are crucial to ensure that medical goods are transported safely and quickly. By keeping an eye on the condition of your carriers, you can avoid unnecessary disruptions to your hospital’s operations and protect the quality of patient care.

If you’re unsure about the current condition of your pneumatic tube carriers or need assistance with maintenance, contact us today. We’re here to help you keep your system running at its best, ensuring that critical medical goods are always delivered where they’re needed, when they’re needed.